Resistance Welding Products | Copper & Tin Based Master Alloys | High Copper Alloys | Products For Electrical Applications | Red Phosphorus

High Copper Alloys :

We are a leading manufacturer, supplier and exporter of High Copper Alloys, which are made of Chromium Copper Rods / Alloys, Chromium Zirconium Copper Alloys, Beryllium Copper Alloys, Tellurium Copper Alloys and Nickel Silicon Chromium Copper Alloys. These are high-conductivity, precipitated hardened copper alloys with better mechanical properties compared to the pure copper. We offer these in the forms of electrodes, rods, bars, wheels and blocks. Sizes of the products are available as per the customer's specific requirements.

- Chromium Zirconium Copper

- Nickel / Cobalt Beryllium Copper

- Nickel Silicon Chromium Copper

- Beryllium Copper

- Tellurium Copper

- Zirconium Copper

Electrodes, Rods and Bars, Wheels, Blocks

Sizes :

As per customer request.

|

|

|

|

Chromium Zirconium Copper AlloysA high strength, high conductivity alloy for spot, seam, butt and projection welding and electrical disconnectors, suitable for plain as well as coated & galvanized sheets.Indian Standard : IS 8365 International Standards : ASTM C-18150, DIN 17666 WN 2.1293, BS 2874 CC 102, ISO CuCrZr. Chemical Composition:

Mechanical Properties:

Physical Properties

Nickel / Cobalt Beryllium Copper AlloysHas higher strength but lower conductivity compared to CrZrCu. Suitable for spot, seam projection welding particularly stainless steel and high.temp. high strength steels.Indian Standard : IS 8365 International Standards

Chemical Composition : (%)

Physical Properties

Mechanical Properties:

2% Beryllium Copper AlloysHas extensive hardness and strength comparable to steels with higher conductivity and softening temp. Suitable for electrode holders, shafts of seam welding machines, inserts for dies and load bearing components.Indian Standard : IS 8365 International Standards ASTM B196 C-17200, DIN 17672 WN2.1247, ISO CuBe2 Chemical Composition: (%)

Physical Properties

Mechanical Properties:

Tellurium Copper AlloysHas very high conductivity (90% IACS) and high machinability (90) making it suitable for electrical parts that require extensive machining particularly on automatic/CNC machines. Particularly suitable for gas nozzles and electrical components.International Standards ASTM B301 C-14500, DIN 17666 WN 2.1546, BS 2874 C 109, ISO CuTe Chemical Composition: (%)

Physical Properties

Mechanical Properties:

Zirconium CopperA moderate strength, high conductivity alloy for spot and seam welding of Aluminium Alloys & Bronzes, Rotor Bars & Rings for electric motors, switches & circuit breakers.Indian Standard : IS 8365 International Standards : ASTM C-15000, DIN 17666 WN 2.1580, BS 2874 CW 120 C, ISO CuZr. Chemical Composition:

Mechanical Properties:

Physical Properties

|

Nickel Silicon Chromium Copper

Nickel Silicon Chromium Copper has Higher strength but lower conductivity compared to CrZrCu. Suitable for spot, seam, projection welding particularly in stainless steel and high temp. and high strength steels. Properties and application of NiSiCrCu are same as Ni/CoBeCu but it is a beryllium free alloy.

Indian Standard : IS 8365 International Standards

Chemical Composition: (%)

Physical Properties :

Mechanical Properties:

|

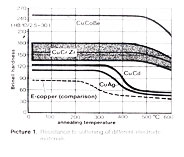

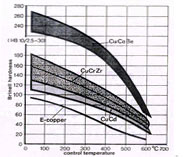

Resistance to Softening : It is the property of a material to come back to its original hardness when it is heated to a certain temperature range for a given time and is then cooled at room temperature. Resistance to Softening : It is the property of a material to come back to its original hardness when it is heated to a certain temperature range for a given time and is then cooled at room temperature. Hardness at high temperature : The hardness of an electrode material at a given temperature (above room temperature) is a criterion for its service life. Hardness at high temperature : The hardness of an electrode material at a given temperature (above room temperature) is a criterion for its service life.Sizes for Copper Chromium, Beryllium Copper & Copper-Nickel-Silicon

|

Products for Electrical Applications :

We are a globally prominent & popular manufacturer, supplier and exporter of a wide range of Alloys like Chromium Copper Rods / Alloys, Chromium Zirconium Copper Alloys, Beryllium Copper Alloys, Tellurium Copper Alloys, Nickel Cobalt Beryllium Copper Alloys, Phosphor Tin Alloys, Nickel Silicon Chromium Copper Alloys and Copper Phosphorus Alloys in various forms and sizes for numerous Electrical Applications to International Standards. These products have very high softening temperature, conductivity, good strength at working conditions, and very long life as compared to the pure copper.

Alloys :

- Chromium Zirconium Copper

- Zirconium Copper

- Tellurium Copper

- Nickel/ Cobalt Beryllium Copper

Forms :

Flat Bars, Strips, Rings, Rods, Machined Components, Contact Fingers.

Sizes :

As per the customer’s specific requirements.

Applications :

|

- Traction Motors

- Large Electric Motors

- Switchgears

- Starters

- Cummutators

- Power Transformers

- Rectifiers

- Disconnectors

- Circuit Breakers

| Resistance Welding Products | Copper & Tin Based Master Alloys | High Copper Alloys | Products For Electrical Applications | Red Phosphorus |