About Us

About Us

M/S CHEMAC Equipments Pvt.

Ltd.

M/S CHEMAC Equipments Pvt.

Ltd. was established in the year 1990 by a group of Mechanical, Chemical,

Process engineers & Chemists having experience in industrial research, design,

development and fabrication.

The company is engaged in multiple activities comprising process development,

designing equipment, fabrication, installation, and implementation of process

technology. It has acquired recognition as the manufacturer of first quality

process equipment in the field of chemicals, pharmaceuticals, ayurvedic products,

cosmetics, food processing.

The work shop situated at Saphed Pool Sakinaka, Mumbai.( INDIA ) is well equipped

with the most modern fabrication equipment to conduct the activity of fabrication

at the highest standards as per GMP, cGMP, ASME, TEMA, etc. The people working

in the workshop are well trained and are constantly informed of the latest techniques

in fabrication of process equipment.

The company also supplies very sophisticated, highly useful R & D Pilot

Scale Equipments Specially designed to suit the requirements of Research &

Development chemists and engineers. Those who are already using this equipment

are extremely happy to work with it since it provides ample data in terms of

mass and energy whenever needed. The entire information regarding such equipment

is attached herewith.

Products

Products

We are manufacturers and suppliers

of Chemical Machineries , Pharmaceutical Machineries , Bulk Drugs, Ayurvedic, Turnkey

Projects & Pilot Plants.

Pharmaceutical machineries: Sifter, Vibro Sifter, Vibro Sifter with Agitator

& under Vacuum, Multi Mills, Pneumatic Tipper Units, Ointment Machinery,

Drum Melter by Steam, Jet Mill (Micronizer), Tablet Coating Pan, Liquid Filling

etc.

Chemical machineries: Reactors, Autoclaves, Storage Tanks & Vessels,

Hydrogenerator, Columns, Condensers, Heat Exchangers, Pressure Vessels and other

process Equipments, Nitrous Oxide Plant, High Vacuum Distillation Unit, Multipurpose

R &D Pilot Plant, Rotary Valves, Vacuum Evaporators etc.

Mixers & Blenders : Mass Mixer, Sigma Mixer, Cream Mixer, Planetary

Mixer, Toffee Mixer, Tempering Pan, Rapid Mixer Granulator, Fondant Mixer, Screw

Mixer, Contra Rotary Mixer, Ribbons Blender with double Choppers, Powder Dozing

System (Screw Conveyor), Double Cone Blender, 'V' Cone Blender, Octagonal Blender

etc.

Dryers : Agitated Vacuum Dryer with Mechanical Rake, Double Cone Vacuum

Dryer, Vacuum Tray Dryer, Tray Dryer with all cGMP Models, Fluid Bed Dryer with

PLC & Fully automatic with Raking Arrangements etc.

Ayurvedic Plant : Aloe Vera Gel & Powder Unit, Steam Distillation

Unit, Multipurpose Solvent Extraction Unit etc.

Liquid Machineries : Stirrers, Agitators, Emulsifiers, Reactors etc.

Other Plants : Total Powder Handling System, Complete Chocolate Manufacturing

Plant.

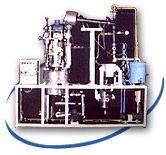

R & D Pilot Reaction / Distillation

/ Fractional Unit

R & D Pilot Reaction / Distillation

/ Fractional Unit

FUNCTION

To facilitate carrying out a wide variety of reactions including condensation,

polymerization, esterification, etherification hydrolysis, hydration, reduction,

oxidation, hydrogenation etc. at low pressures and at high pressures and

at temperatures ranging -200C to +2500C. FUNCTION

To facilitate carrying out a wide variety of reactions including condensation,

polymerization, esterification, etherification hydrolysis, hydration, reduction,

oxidation, hydrogenation etc. at low pressures and at high pressures and

at temperatures ranging -200C to +2500C.

CAPACITY 10 to 500 Litres.

SALIENT FEATURES The entire unit is designed

to conduct all the operations smoothly and Safely. The stirrer speed can

be adjusted from 10 to 400 RPM with a helical / cyclo gear control motor

and speed selector. The facility provides for deriving accurate data on

material as well as energy balances.

|

Versatile Fractional Column with Vapourization

Under Forced Circulation

Versatile Fractional Column with Vapourization

Under Forced Circulation

FUNCTION

To fractionally distil sensitive multi-component mixtures under highly controlled

heating conditions whilst maintaining a constant ratio of quality of liquid

to area of heating. FUNCTION

To fractionally distil sensitive multi-component mixtures under highly controlled

heating conditions whilst maintaining a constant ratio of quality of liquid

to area of heating.

CAPACITY 30 lits. to 10000 ltrs.

SALIENT FEATURES Falling film type of

heating exchanger provided at the reboiler with a totally leak proof pump

with mechanical eal ensures high heat transfer coefficient and facilitates

vaporisation of the liquid maintaining minimum temprature differential between

the source heat and the boiling point of the liquid at the operating pressure.

|

Ribbon

Blender with Double Chopper Ribbon

Blender with Double Chopper

FUNCTION

To mix, crush and blend solid powders efficiently FUNCTION

To mix, crush and blend solid powders efficiently

CAPACITY 20 liters onwards.

SALIENT FEATURES The entire unit is fabricated

with engineering precision. Along with the double ribbons which provide

to & fro, up & down movement to the powder. 2 nos. chopper blades

moving at cutting speed are provided at diagonally opposite sides to break

lumps / coarse particles of the mixture.

|

Agitated Vacuum Dryer With Mechanical Rake

Agitated Vacuum Dryer With Mechanical Rake

FUNCTION

To dry heat sensitive and air sensitive material under vacuum thus accomplishing

the drying at moderate temperature avoiding contact with air. FUNCTION

To dry heat sensitive and air sensitive material under vacuum thus accomplishing

the drying at moderate temperature avoiding contact with air.

CAPACITY 5 litres onwards (Chamber Size).

SALIENT FEATURES The entire drying chamber

is well machined to bring about a close encounter with the agitator blade

thus ensuring proper shuffling of the material and thus avoiding localised

over heating. The leak proof front opening door ensures easy cleaning of

the entire chamber. |

Air Tray Dryers

Air Tray Dryers

Temprature uniformity ensured

by an effective air distribution, which homogeneously reaches every section

of the chamber. Walls internally welded in order to eliminate environmental

pollution according to the most stringent standards of cGMP. Theemal insulation

according to good engineering practice and current regulation. Easy access

for maintenance to the heating, ventilation and cooling groups (cooling

installed in sterilizing ovens only). Detached control board featuring maximum

installation flexibility. Filtration of both incoming and outgoing air through

effective chamber protaction. Temprature uniformity ensured

by an effective air distribution, which homogeneously reaches every section

of the chamber. Walls internally welded in order to eliminate environmental

pollution according to the most stringent standards of cGMP. Theemal insulation

according to good engineering practice and current regulation. Easy access

for maintenance to the heating, ventilation and cooling groups (cooling

installed in sterilizing ovens only). Detached control board featuring maximum

installation flexibility. Filtration of both incoming and outgoing air through

effective chamber protaction.

|

Drum Melter

Drum Melter

FUNCTION

Heat exchangers dor drum warming. FUNCTION

Heat exchangers dor drum warming.

CAPACITY Suitable for design pressures

5 kg/cm2

Heating conditions : For steam - 1 to 4 Kg/cm2 , Temperature - 70°C

For Oil temperature - 200°C

SALIENT FEATURES The Drum Melter is available

with two type of standard and saddle types, vertical and saddle type.

It is the compact model on castor wheels. A common header is provided for

inlet and outlet connections. There is a special provision of heating bottom

part of the drum so that it can heat or cool the drum so that it can heat

or cool the contents from bottom. Mounting of drum is easier.

|

Vacuum Tray Dryers

Vacuum Tray Dryers

FUNCTION

Used mainly for drying of high grade, temperature and oxygen sensitive products. FUNCTION

Used mainly for drying of high grade, temperature and oxygen sensitive products.

CAPACITY Standard models range from 4

trays to 48 trays.

SALIENT FEATURES Bodies may be of cylindrical

or rectangular cross section. Both shelves and body are heated ( the body

to prevent internal condensation) with controlled circulation of hot water,

steam or diathermic fluid. Vacuum is drawn through large diameter ducts

to minimize pressure drops and produce minimum working pressures.

|